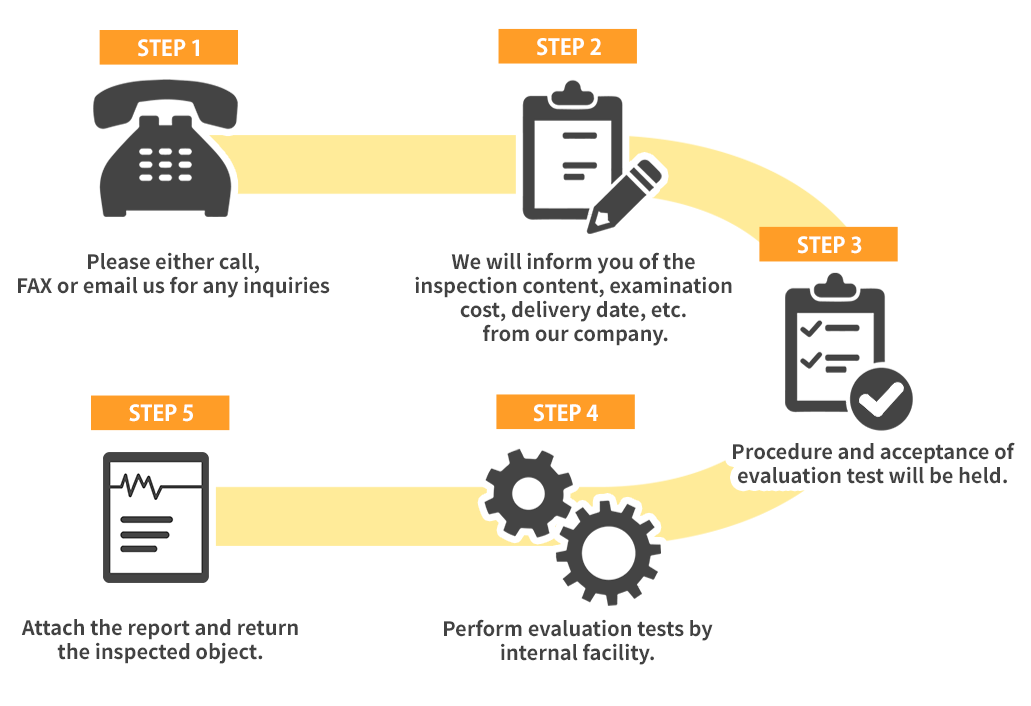

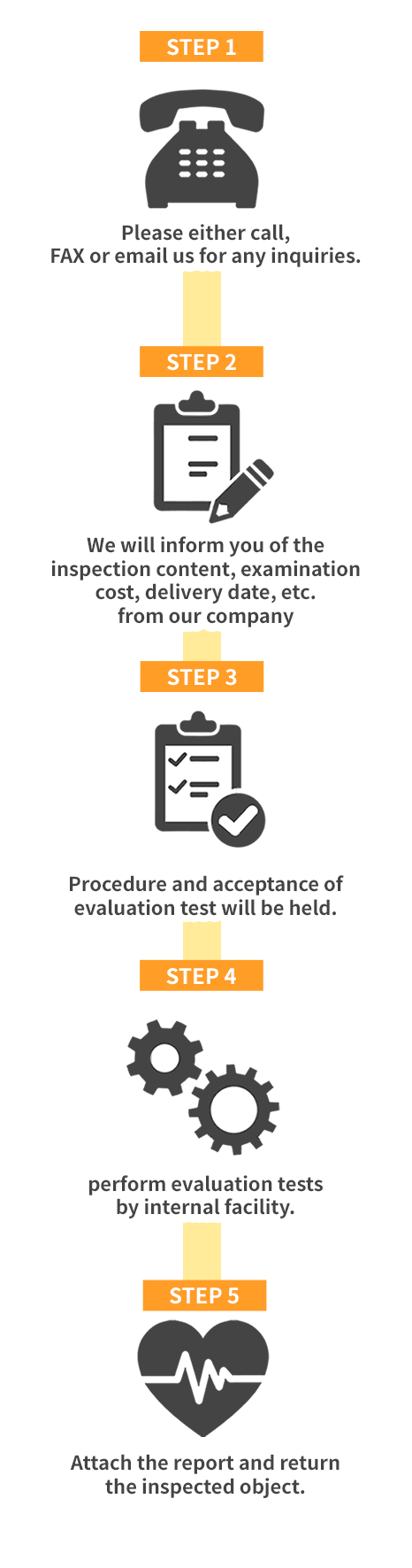

Flow of the Consignment test

The Consignment Testing

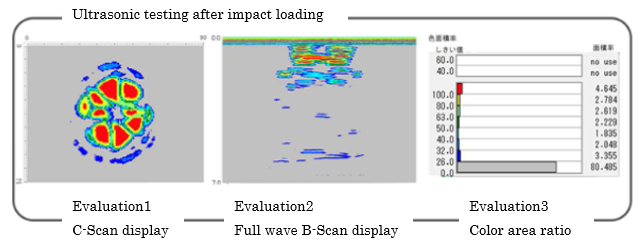

●Ultrasonic testing of composite material

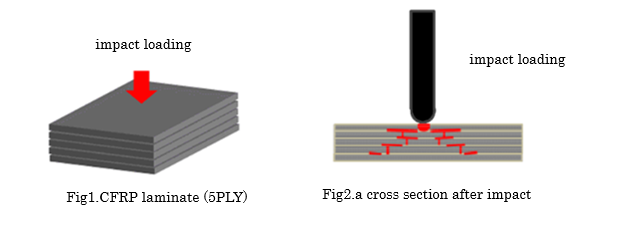

The original fatigued crack in the Carbon fiber reinforced plastics (CFRP) called transverse crack or matrix crack progresses alternately with delamination. In Ultrasonic testing of CFRP, there are cases when it reduces discrimination by the effect of reflection from the boundary of lamination layer, fibers, and voids.

Our company will use the technical strengths it developed for the aerospace field to accept the consignment testing of CFRP moldings.

The defects in CFRP are progressed by crack and delamination alternately when it is got an intensive load on surface part, and the delamination expands toward under layers as shown in Fig. 2. Therefore, there are cases where the delamination widely expands in internal even if it looks small on the surface.

The following are examples of evaluation method.

The main products which is targeted for the quality evaluation

●Parts and materials such as Automobiles and Aerospace/Airplane industries.

●Quality evaluation of CFRP molded products, different materials, and etc.

If you would like a non-destructive inspection of products and materials not listed above, please don’t hesitate to contact us.

The evaluation method is different, depending on the items to be inspected.